Simon Fraser University (SFU) is a leading research university, advancing an inclusive and sustainable future.

We consistently place among the country's top 15 research universities in global and national university rankings systems.

Scholarly Impacts

Updated weekly, SFU's Scholarly Impact of the Week is selected by the Office of the Vice-President, Research and Innovation to celebrate scholarly milestones and research impacts from across the SFU research community.

Research News

SFU delivers academic and research excellence to harness new ideas and innovations for the benefit of society.

Research support

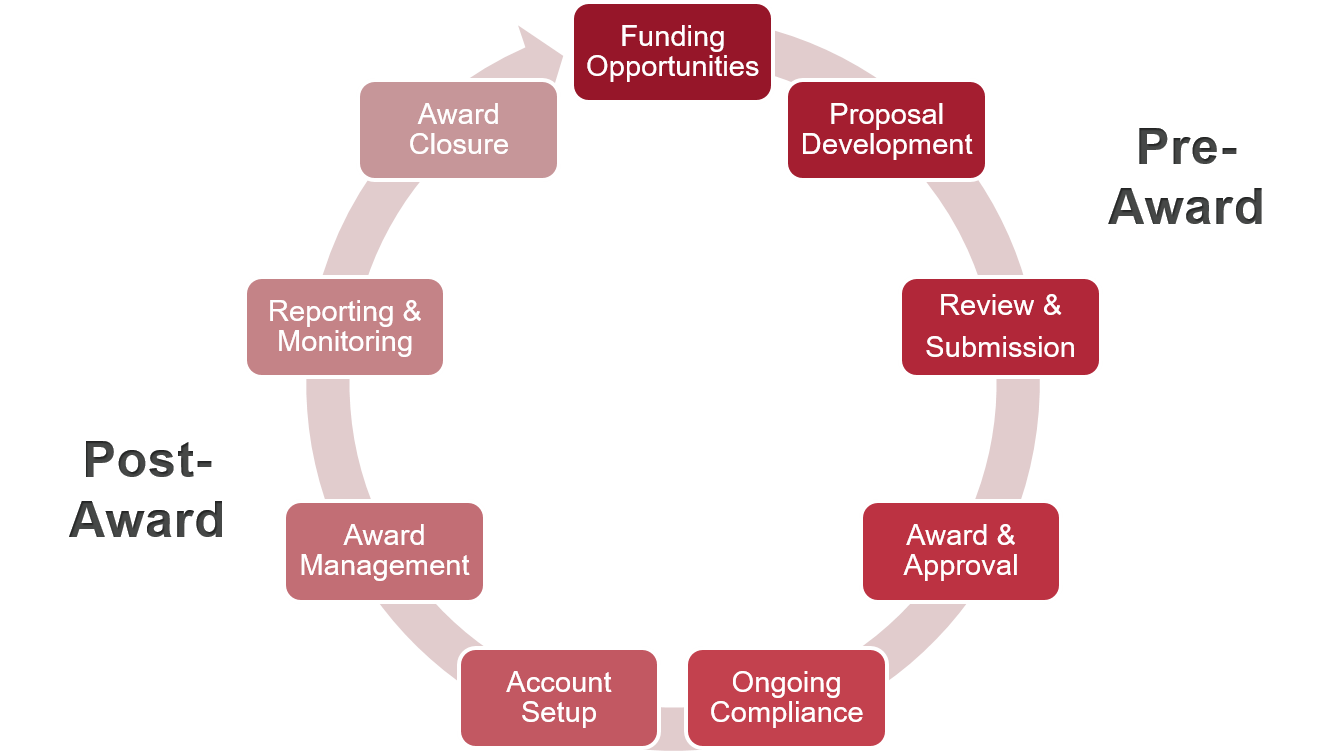

Find research funding. Get support at any stage of your research project. Mobilize the results of your research.